Today’s production facilities operate through industrial equipment, which supports all manufacturing operations including vehicle construction, aircraft assembly, building development and food production and heavy engineering projects. The high demand and pressure on the industrial equipment are exposed to wear and tear as well as corrosion. These machines also face heat overloads and accidental damage. Given the need for maintaining machine uptime, there’s need for sound protective technology investments within industrial equipment.

Protective Coatings: Corrosion and Wear Protection

Protective coating implementation becomes essential for industrial equipment protection against premature wear. They function as a defense layer to stop corrosion impacts along with blocking abrasive harm and substance degradation and atmospheric exposure.

Types of Protective Coatings

- Powder Coatings: Powder coating is applied to create durable, high-quality finishes to metal surfaces that do not fade and can resist both scratching and chipping and breaking. Ideal for metal surfaces.

- Ceramic Coatings for High-Heat Applications: The high resistance to heat and corrosion also makes them suitable for installation in furnaces alongside engines.

- Polyurethane Coatings for Chemical Resistance: The anti-chemical and flexible properties of polyurethane coatings make these coatings suitable for organizations that require intense cleaning chemicals.

- Epoxy Coatings for Industrial Protection: Epoxy Coatings demonstrate strong resistance to corrosive chemicals; thus, manufacturers often use them in manufacturing facilities and chemical production areas.

As part of the Protective Solutions for Industrial Machinery, coatings improve the durability of machine components, which minimizes equipment downtime and maintenance expenditures.

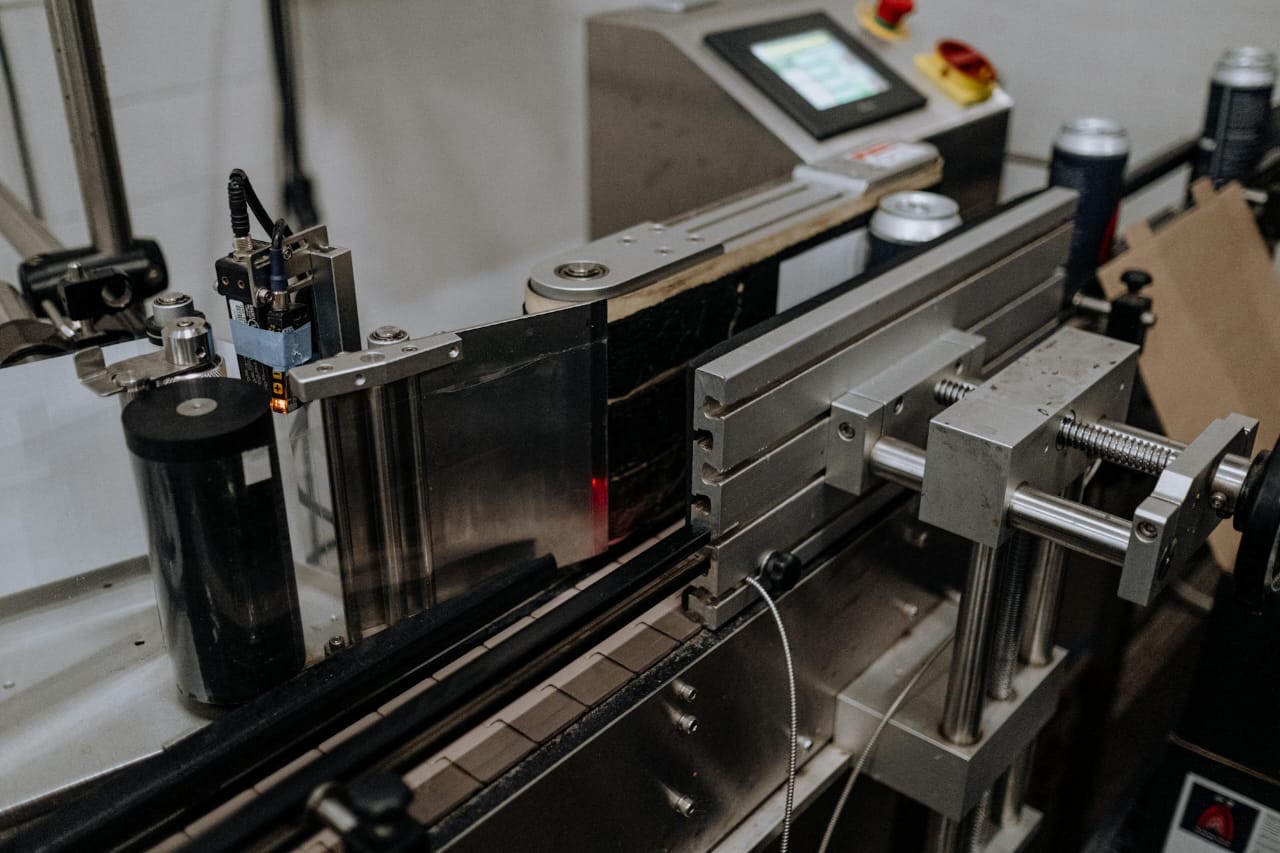

Enclosures and Guards: Prevention of Outside Damage

Machine enclosures alongside guards protect equipment from weather elements, prevent bumps, and keep machinery safe from human handling. Protective Solutions for Industrial Machinery helps extend equipment life span and simultaneously creates safer working environments at the workplace.

Types of Machinery Enclosures

- Mechanical Enclosures: Protect equipment from multiple environmental risks, such as accidental contact and dust and moisture invasion. Suitable for outdoor and industrial applications.

- Acoustic Enclosures: Avoid noise pollution in the workplace, safeguarding employees from high noise levels.

- Safety Barriers and Guards: Barriers along with safety guards, serve to protect workers from moving equipment contact, thus preventing workplace injuries.

Occupational Safety and Health Administration (OSHA), together with other safety agencies, makes it mandatory to use safety guards throughout factory work areas to prevent accidents.

Cooling and Thermal Management Systems

Excessive temperature may cause equipment to break down, decrease efficiency, and increase the cost of operation. Utilization of effective cooling systems maintains equipment at appropriate temperatures.

Major Cooling Methods

- Air Cooling: Air ventilation systems and fans are used to dispel heat from industrial machinery.

- Liquid Cooling: Passes coolant through elements of machines for efficient temperature regulation.

- Heat Shields: Deflect heat from heat-sensitive components, minimizing thermal stress.

- Radiators and Heat Exchangers: Eliminate equipment waste heat into cooling liquids in order to achieve thermal stability.

Successful thermal management enhances machine efficiency and reduces the potential for heat-related failure.

Vibration Control and Shock Absorption

Industrial equipment is subjected to severe shock and vibration, causing mechanical stress and wear. Vibration control techniques increase stability and optimize the life of the equipment.

Common Vibration Isolation Methods

- Damping Materials: These dissipate and absorb vibration energy, reducing mechanical stress.

- Shock Absorbers: Restrict the level of force passed on to machine members.

- Mounting Pads and Isolators: Limit the vibrations transferred to the surrounding structures.

- Dynamic Balancing: Causes rotating components to rotate smoothly without generating imbalances that are likely to result in wear and tear.

Controlling vibration increases the life of machines and improves accuracy in precision industries like aerospace and electronic manufacturing.

Lubrication and Preventive Maintenance

Lubrication is a critical component of equipment protection, minimizing friction and avoiding premature wear. Equipment reliability is also increased through a complete preventive maintenance program.

Successful Lubrication Strategies

- Automatic Lubrication Systems: Release precise amounts of lubricants at regular intervals, reducing human interaction.

- Synthetic Lubricants: Offer more excellent thermal stability and longevity compared to conventional oils.

- Grease Application: Most effective for components with heavy loads and harsh conditions.

Preventive Maintenance Practices

- Regular Inspections: Catch problems before they result in breakdowns.

- Condition Monitoring: Uses sensors and IoT capabilities to track machine performance in real-time.

- Scheduled Servicing: Maintains parts in top form, reducing surprise failures.

An effective maintenance strategy minimizes downtime and enhances overall productivity.

Dust and Contaminant Protection

Equipment efficiency decreases because dust, together with debris and contaminants, enter the devices to cause system clogs and equipment corrosion. Precautionary procedures exist to reduce these possible risks.

Protective Measures Against Contaminants

- Seals: Seals are used to shield bearings and machine components from dust and moisture.

- The filtration system: Filters out particles from air as well as liquid elements to guarantee clean operation.

- Positive Pressure Enclosures: These function to stop contaminants by keeping interior air pressure higher than outside conditions.

- Regular Cleaning Routines: High hygiene must be implemented to prevent toxic residue buildup on machine surfaces.

Modern manufacturing facilities, including food production companies, drug makers and electric equipment manufacturers, need strong contamination protection systems to preserve product quality and enhance equipment durability.

Electrical Protection Solutions

Industrial machines operate with complicated electrical network systems that face problems due to surges and short circuits and become vulnerable to external pressure. Equipment damage, together with harm to humans, becomes avoidable through proper electrical protection measures.

Electrical Protection Techniques

- Breakers: Circuit Breakers, together with Fuses, operate as protective devices that disconnect dangerous over currents to stop equipment heating and potential fire hazards.

- Grounding Systems: Electrical currents through grounding systems allows for safe ground-based power dissipation while preventing hazardous electric shocks.

- Waterproof and Fire-Resistant Materials: Waterproof and fire-resistant cable covers protect wiring from exposure to the elements.

The implementation of electric safety standards leads to dependable equipment operations while minimizing maintenance costs.

Protective measures for industrial machinery remain essential because they lead to higher operational efficiency as well as lower downtime occurrences while machines experience longer functional life. Protective measures such as the installation of coatings and enclosures along with cooling systems vibration control technologies, as well as preventive maintenance programs, improve workplace efficiency and security. Proper protective investments lead to financial savings and lead to better reliability alongside improved efficiency of industrial equipment in the long term. Active risk management steps employed by industries enable them to operate without risks and become top performers in a growing market sector.